Project Description

WC67K Series Automatic NC Metal sheet Sheet fab Press Brake with E21 Controller System

Machine Instroduction

·Complete steel-welded structure, with sufficient strength and rigidity;

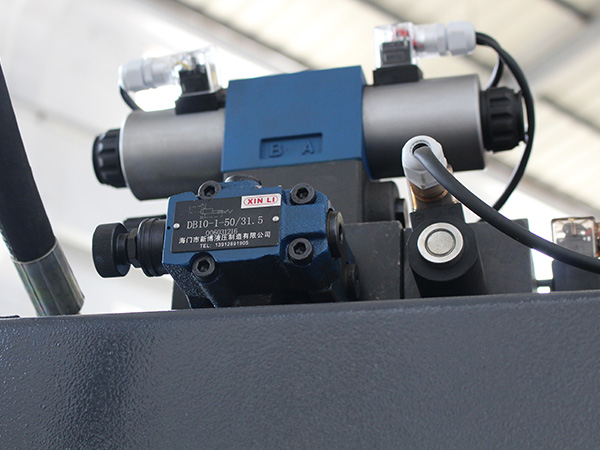

·Hydraulic down-stroke structure, reliable and smooth;

·Mechanical stop unit, synchronous torque, and high precision;

·Back-gauge distance and upper ram stroke with electric adjustment, and counter display;

·Upper tool with tension compensating mechanism, in order to guarantee high precision of bending;

·Eston E21 NC system, DA-41 can be optional;

·E300 for X-axis and Y axis +Crowing automatic control.

·Inclined wedge deflection on the compensation mechanism, in order to guarantee access to high bending accuracy

·Safety barrier device all around the machinery, electrical cabinets equipped with Open door cut-off function, emergency stop button around front and back,

protective cover foot switch to ensure safe working.

E300 controller system -Y,X+Crowning :

3 axes are supported :X-axis,Y axis and C-axis ( worktable crowning )

Automatic calculation of the block position ,according to the bending angle ,material ,thickness ,and mold parameter

The back gauge can be controller in a high accuracy since the servo system control x-axis

Optional hydraulic or mechanical to control the C-axis

Program in absolute value or angle

You can backup ,restore,import and export the parameters ,for commissioning the machine easily .

Edit the program in one page ,for improving the operating efficiency .

You can program the dwell time (holding time ) and retracting delay by the device instead of the time relay .

Interference or collision of the die can be avoided

The opening distance can be adjusted ,for improving the operating efficiency.

Materials and die information are programmable

Three of the operation mode (jog ,single ,continuous )for the jobs .

Language setting and unit setting

IO ports can be allocated freely ,and the device can detect them for avoid the repeat .

Bilaterial positioning and unilateral positioning

Slug clearance function

Teaching or search the reference point

The axis ,which is controlled by a servo system ,can be manually moved .

Real-time memory the parameters ,positions and programs against the unexpected accidents such as interruption of power supply

| Technical Specifications | |||||||||

| Bending Force | Bending Length | Upright Distance | Throat Depth | Stroke | Opening Height | Main Motor | Weight | Overall Dimensions | |

| Kn | mm | mm | mm | mm | mm | Kw | Ton | L×W×H mm | |

| WC67K/E-30t/1600 | 300 | 1600 | 1300 | 200 | 80 | 220 | 5.5 | 2.3 | 1650*1200*1700 |

| WC67K/E-30t/2000 | 300 | 2000 | 1300 | 200 | 80 | 220 | 5.5 | 2.5 | 2000*1150*1700 |

| WC67K/E-40t/2500 | 400 | 2500 | 2030 | 250 | 100 | 340 | 5.5 | 3.5 | 2500*1200*1900 |

| WC67K/E-63t/2500 | 630 | 2500 | 2050 | 250 | 120 | 340 | 5.5 | 4.5 | 2500*1600*2200 |

| WC67K/E-63t/3200 | 630 | 3200 | 2510 | 250 | 120 | 340 | 5.5 | 5 | 3200*1600*2200 |

| WC67K/E-80t/2500 | 800 | 2500 | 2050 | 250 | 120 | 350 | 5.5 | 6 | 2500*1700*2200 |

| WC67K/E-80t/3200 | 800 | 3200 | 2510 | 250 | 120 | 350 | 5.5 | 6.2 | 3200*1700*2200 |

| WC67K/E-100t/2500 | 1000 | 2500 | 2050 | 320 | 120 | 380 | 7.5 | 6.5 | 2500*1500*2200 |

| WC67K/E-100t/3200 | 1000 | 3200 | 2510 | 320 | 120 | 380 | 7.5 | 7 | 3200*1800*2500 |

| WC67K/E-100t/4000 | 1000 | 4000 | 3100 | 320 | 120 | 380 | 7.5 | 8.5 | 4000*1800*2500 |

| WC67K/E-125t/3200 | 1250 | 3200 | 2510 | 320 | 120 | 380 | 7.5 | 7.5 | 3200*1900*2600 |

| WC67K/E-125t/4000 | 1250 | 4000 | 3100 | 320 | 120 | 380 | 7.5 | 9.5 | 4000*1435*2600 |

| WC67K/E-160t/2500 | 1600 | 2500 | 2050 | 320 | 200 | 450 | 11 | 9 | 2500*1900*2700 |

| WC67K/E-160t/3200 | 1600 | 3200 | 2510 | 320 | 200 | 450 | 11 | 11 | 3200*2000*2800 |

| WC67K/E-160t/4000 | 1600 | 4000 | 3040 | 320 | 200 | 450 | 11 | 12 | 4000*2000*2800 |

| WC67K/E-160t/5000 | 1600 | 5000 | 3800 | 320 | 200 | 450 | 11 | 14.5 | 5000*1900*3100 |

| WC67K/E-160t/6000 | 1600 | 6000 | 4600 | 320 | 200 | 450 | 11 | 19.5 | 6000*1900*3300 |

| WC67K/E-200T/3200 | 2000 | 3200 | 2600 | 320 | 250 | 540 | 15 | 13.5 | 3200*1820*3300 |

| WC67K/E-200T/4000 | 2000 | 4000 | 3300 | 320 | 250 | 540 | 15 | 15 | 4000*2000*2850 |

| WC67K/E-200T/5000 | 2000 | 5000 | 3800 | 320 | 250 | 540 | 15 | 19 | 5000*1950*3000 |

| WC67K/E-200T/6000 | 2000 | 6000 | 4600 | 320 | 250 | 540 | 15 | 21 | 6000*1950*3300 |

| WC67K/E-250T/3200 | 2500 | 3200 | 2600 | 400 | 250 | 580 | 18.5 | 17 | 3300*2000*3200 |

| WC67K/E-250T/4000 | 2500 | 4000 | 3300 | 400 | 250 | 580 | 18.5 | 20 | 4000*2000*3400 |

| WC67K/E-250T/5000 | 2500 | 5000 | 3800 | 400 | 250 | 580 | 18.5 | 23 | 5000*2000*3500 |

| WC67K/E-250T/6000 | 2500 | 6000 | 4600 | 400 | 250 | 580 | 18.5 | 25.5 | 6000*2000*3600 |

| WC67K/E-300T/3200 | 3000 | 3200 | 2600 | 400 | 250 | 580 | 18.5 | 21 | 3200*2100*3300 |

| WC67K/E-300T/4000 | 3000 | 4000 | 3300 | 400 | 250 | 580 | 18.5 | 23 | 4000*2100*3500 |

| WC67K/E-300T/5000 | 3000 | 5000 | 3800 | 400 | 250 | 580 | 18.5 | 25 | 5000*2100*3700 |

| WC67K/E-300T/6000 | 3000 | 6000 | 4600 | 400 | 250 | 580 | 18.5 | 27.5 | 6000*2100*4000 |

| WC67K/E-400T/4000 | 4000 | 4000 | 3300 | 400 | 250 | 580 | 22 | 26 | 4000*2200*3600 |

| WC67K/E-400T/5000 | 4000 | 5000 | 3800 | 400 | 250 | 580 | 22 | 32 | 5000*2200*3900 |

| WC67K/E-400T/6000 | 4000 | 6000 | 4400 | 400 | 250 | 580 | 22 | 35 | 6000*2200*4100 |

| WC67K/E-500T/4000 | 5000 | 4000 | 3300 | 500 | 320 | 620 | 30 | 33 | 4000*2400*3900 |

| WC67K/E-500T/5000 | 5000 | 5000 | 3800 | 500 | 320 | 620 | 30 | 37.5 | 5000*2400*3900 |

| WC67K/E-500T/6000 | 5000 | 6000 | 4410 | 500 | 320 | 620 | 30 | 43.5 | 6000*2450*4250 |

| WC67K/E-500T/7000 | 5000 | 7000 | 5400 | 500 | 320 | 620 | 30 | 55 | 7000*2550*4350 |

| WC67K/E-600T/4000 | 6000 | 4000 | 3300 | 500 | 320 | 620 | 37 | 45 | 4000*2700*4700 |

| WC67K/E-600T/5000 | 6000 | 5000 | 3800 | 500 | 320 | 620 | 37 | 48 | 5000*2700*4750 |

| WC67K/E-600T/6000 | 6000 | 6000 | 4600 | 500 | 320 | 620 | 37 | 55 | 6000*2700*4950 |

| WC67K/E-600T/7000 | 6000 | 7000 | 5400 | 500 | 320 | 620 | 37 | 62 | 7000*2700*5150 |