Project Description

QC11K guillotine shearing machine for metal sheet cutting with DAC-310 controller system

The second generation of shear.

Welded steel plate construction, heating to eliminate stress,with high strength and good rigidity.

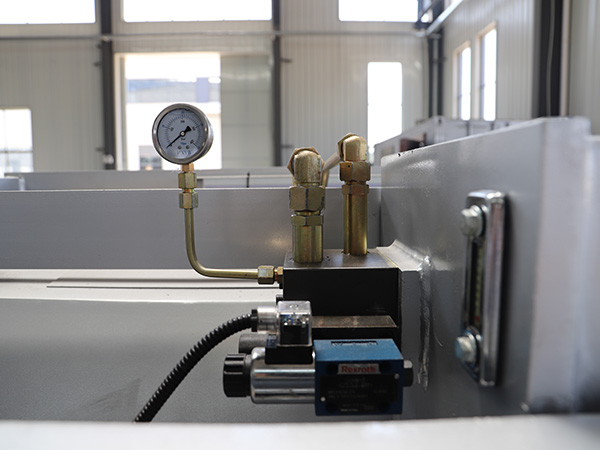

Advanced integrated hydraulic system with and excellent reliabitity quality.

Rapidly,accurately and conveniently adjusting the blade clearance by motor

The adjustable rake angle can minimize plate deformation.

As the cutting beam has been designed in inner-inclined structure,it is easy for plates to fall down and the accuracy of products can be also guaranteed.

Shearing in sections,shadow-line cutting.

Counter for the motorized back gauge.

Back support device (optional).

Standard Equipments:

Hardened blades.

– Top blades : 2 sides

– Bottom blades : 4 side600mm motorized backgauge system with 0,1 mm accuracy.

800mm side gauge and front support arms.

Metric and inch rulers.

Front, side and back safety panels which are suitable for CE norms.

Sheet sliding system.

Schneider Electric System.

Rexroth hydraulic system.

Moveable foot pedal.

Manual blade gap adjustment.

Emergency stop button.

Collapsible finger protection.

| Machine Paramters | |||||

| model | Shearing Thickness | Shearing Width | Strokes | Back gauge Range | Shearing Angle |

| (mm) | (mm) | (time/min) | (mm) | (.) | |

| 4*3200 | 4 | 3200 | 18 | 20-500 | 1 30’ |

| 6*3200 | 6 | 3200 | 14 | 20-500 | 1 30’ |

| 8*3200 | 8 | 3200 | 12 | 20-500 | 1 30’ |

| 10*4000 | 10 | 4000 | 12 | 20-600 | 1 30’ |

| 12*6000 | 12 | 6000 | 6 | 20-600 | 1 30’ |

| 12*8000 | 12 | 8000 | 5 | 20-600 | 1 30’ |

| 16*3200 | 16 | 3200 | 12 | 20-600 | 2 |

| 16*4000 | 16 | 4000 | 8 | 20-600 | 2 |

| 20*4000 | 20 | 4000 | 5 | 20-600 | 2 30’ |

| 25*4000 | 25 | 4000 | 6 | 20-600 | 2 30’ |

| 32*3200 | 32 | 3200 | 5 | 20-600 | 3 |

| 40*3200 | 40 | 3200 | 5 | 20-600 | 3 |

| 50*3000 | 50 | 3000 | 5 | 20-600 | 3 |

| 50*6000 | 50 | 6000 | 5 | 20-600 | 3 |

| 60*3500 | 60 | 3500 | 5 | 20-600 | 3 30’ |