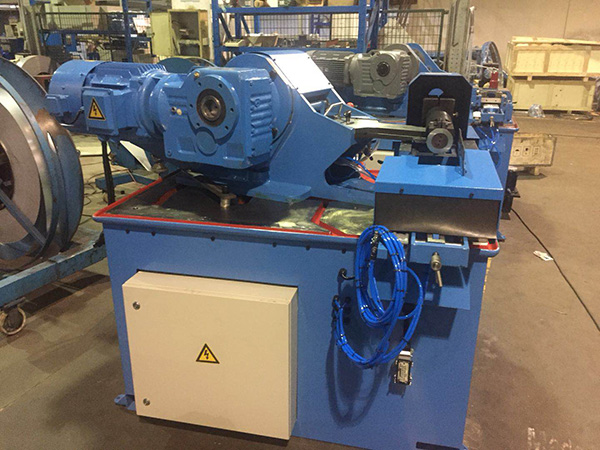

Project Description

Round Duct Making Machine Spiral Tubeformer 1602

Main Features:

Diameter range: 100-1600mm

Thickness: 0.4-1.2mm

Feeding speed: 0-35m/min

The flanging and seaming is the tightest ever detected on the market by independent research institutes.

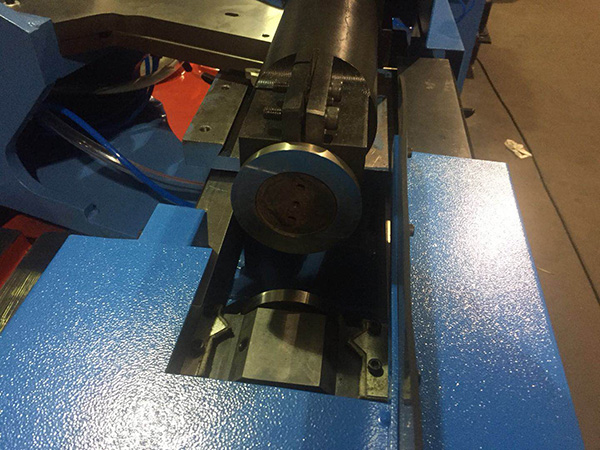

All key parts are made of high quality die steel.

The unique roll pattern on the drive roller optimizes the force.

Special angle blade optimize shear.

The special inlaid copper piece of the molding head minimizes friction and makes it more durable.

The precision work differential of the forming roll assembly optimizes the edge seam.

The blade uses high-quality steel with long service life.

The special clamping roller makes the edge seam firm.

With high efficiency, the conveying speed of the belt can reach up to 80m/min.

Compact structure and occupy a small area.

The forming machine bed and base plate are made of ductile iron with good stability and no deformation.

Adopt multiple protection devices with good safety performance.

The decoiling machine with unique material tensioning device, improve the precision and quality of products.

Hydraulic system, stable operation, low noise, easy maintenance.

The hydraulic system is safe, reliable and easy to adjust.

Multi-step programming, automatically program running.

It has power off protection function to ensure the parameter is not lost.

| Technical Data | |

| Model | DMTF-1602 |

| Diameter range (mm) | Φ80-Φ1600 |

| Thickness of strip (mm) | 0.4-1.3(GI) / 0.4-0.8 (SS) /1.4-1.3(Alu) |

| Strip width (standard) (mm) | 0.4-1.0mm 137mm/ 1.1-1.3mm 140mm (standard ) |

| Max working speed( m/min) | Max 60 meters/min depending on material |

| Corrugations | Either one or two beads |

| Lockseam | Outside tube ,on the inside on the request |

| Cutting system | The patented flying slilter |

| Power (KW) | main frame :11kw / cooling system :0.25KW |

| Weight (KG) | 2900 |

| Dimension (MM) | 2000*1700*1450 |