Project Description

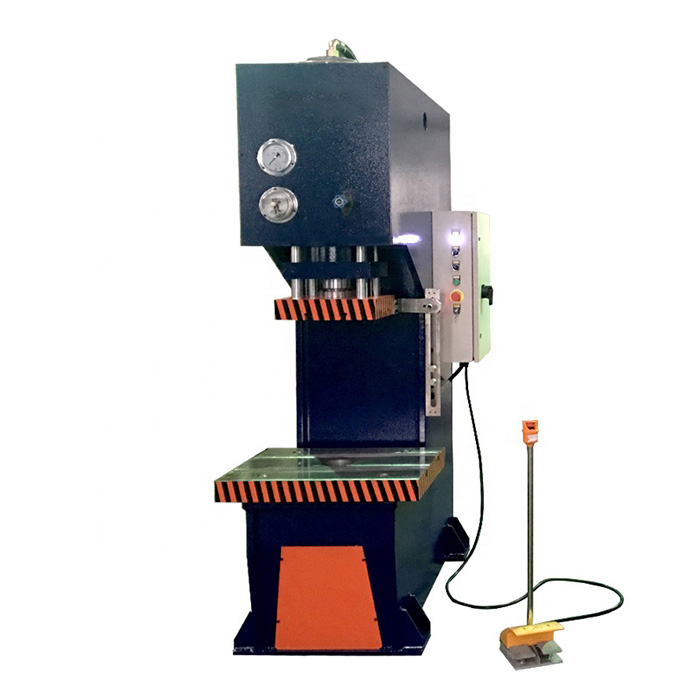

YDDM32 Series 100T four column hydraulic press with factory price

Machine Features:

Hydraulic transmission, low noise, complete functions, high production efficiency, optimized structure design, stable and reliable

Solid open structure welded as a whole can maintain enough rigidity of the fuselage and provide the most convenient operation space

The press stroke of this series of presses is generally controlled by timer, pressure switch, position sensor, or the customer’s own mold

Suitable for blanking, bending, flanging, sheet stretching, fine blanking and cold extrusion of metal parts

Adjustable pressing force, no overload, realize the pressure maintaining and delay requirements of each step in the pressing process

The rise height of the pressure mounting spindle can be adjusted within the travel range of the timer or position sensor

Low oil pump displacement, low motor power, power saving and energy saving

Centralized button with manual, semi-automatic and automatic operation

hydraulic statistics within the built-in frame, neat appearance, lightweight, stable

Optional parts :

Move the workbench

Blanking buffer device

Pressure regulating device for pressing edge slider and hydraulic pad (stretching asymmetric parts)

Photoelectric protection device

touch with floating guide rail and rolling bracket

Mould quick clamping mechanism

Stroke, pressure and degree display and control

Touch industrial display screen

Heating and cooling device and alarm system of hydraulic system