Project Description

CF- 4020 Series fiber laser tube cutting machine with exchange table and protection cover

Machine features

Application of gantry structure and integrated cast cross-girder to achieve higher rigidity, stability, shock resistance.

High-performance laser source and stable operating system which make the best cutting effect.

The machine owns perfect cooling system, lubrication system and dust removal system, to ensure that it can operate stably, efficiently and durably.

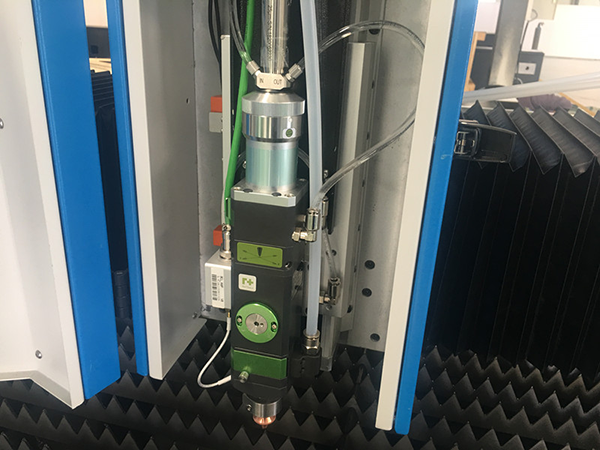

The machine is capable of automatic height adjustment to maintain constant focal length and stable cutting quality.

The machine is used for cutting a variety of metals with excellent and stable cutting quality.

The specialized CAD / CAM automatic programming software and automatic nesting software aim to maximally save raw materials.

Access to the CNC system through Ethernet interface makes communication and remote monitoring possible during the laser cutting process.

| Main parts | |

| LASER SOURCE | RAYCUS LASER |

| CUTTING HEAD | RAYTOOLS BT-240 |

| LATHE BED | DDMLASER |

| DRIVE MODE | DUAL DRIVE |

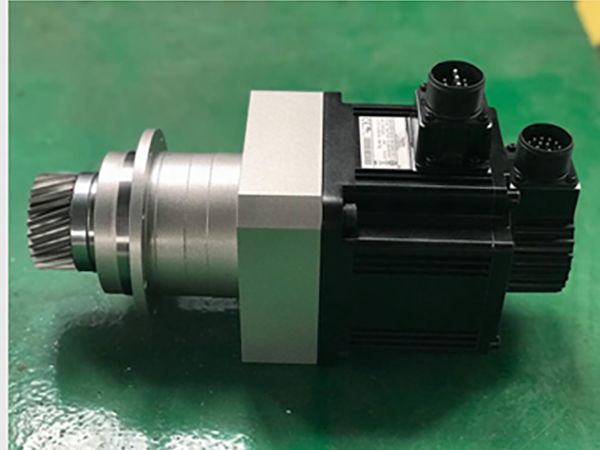

| TRANSMISSION | TAIWAN RACH AND PINION |

| GUIDE RAIL | TAIWAN |

| SERVO MOTOR AND DRIVER | 4 SETS OF FUJI FROM JAPAN |

| REDUCER | FRANCE MOTOREDUCER |

| WATER CHILLER | HANLI |

| CONTROL SYSTEM | CYPCUT FROM SHANGHAI, CHINA |

| COMPUTER | ADVANTECH INDUSTRY COMPUTER |

| POWER REQUIREMENT | 3 PHASE AC 380V 50HZ |

| GROSS WEIGHT | 3.00MTS |

| TERMINAL ROW | GERMANY WEIDMULLER |

| RELAY | FRANCE SCHNEIDER |

| SOLENOID VALUE | TAIWAN AIRTAC |

| PROPORTIONAL VALUE | JAPANESE SMC |

| WORKING SIZE | 4000*2000 MM |