Project Description

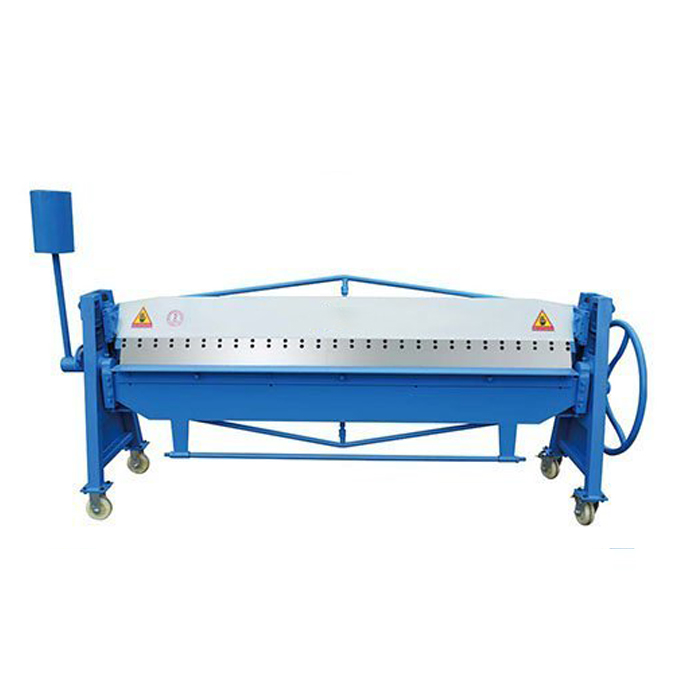

AutoFlex Duct Connector Roll Forming Line

AutoFlex Duct Connector Roll Forming Line – it is composed of Feeding ,Oval hydraulic punching , roll forming,Notching (optional) and Cutting.

The whole lines is for making the duct connector which is widely used in round duct and squre duct connection .

Specification

1. Hydraulic punching;

2. hydraulic automatic cutting;

3. the main control box is Schneider, the encoder is Japan Omron, PLC and inverter are Taiwan Delta and the hydraulic cylinder is Taiwan

Jiagang;

4. consist: two decoilers (bearing weight less than 800kg), hydraulic servo feeder, 2 sets of hydraulic punching moulds, main machine, and a holder.

Main Parameters:

Thickness of galvanized steel: 0.4-0.8mm

Width of galvanized steel: 50-150mm

Width of fireproof cloth: 100-300mm

Width of final product: 140-540mm

Technical Data:

| Model | DDM-500 |

| Suitable Material | Stainless steel, Galvanized steel , Fireproof fabric. |

| Motor power | 7.5+3+0.75 KW |

| Forming speed | 1-10m/Min |

| Max width (final products) | 140- 540mm |

| Metal Sheet thickness | 0.4-0.8mm |

| Shaft material | Cr12 steel, quench HRC58-62, Chrome plate |

| Weight | 2500Kg |

| Diemension | 3500 x 1200 x 1500mm |

| Roller station | 12 Stations |

Relate Square Duct Machine Products:

ddmchinaadmin2020-08-07T06:22:39+00:00

ddmchinaadmin2024-04-06T08:48:30+00:00

ddmchinaadmin2020-08-07T05:59:58+00:00

ddmchinaadmin2020-08-07T05:56:59+00:00

ddmchinaadmin2020-08-07T05:54:43+00:00

ddmchinaadmin2020-08-07T05:49:48+00:00