Project Description

QC12K cnc shearing machine for metal sheet cutting with E21 controller

The Frame is entirely welded with steel plates, and treated to relive stress by tempering.

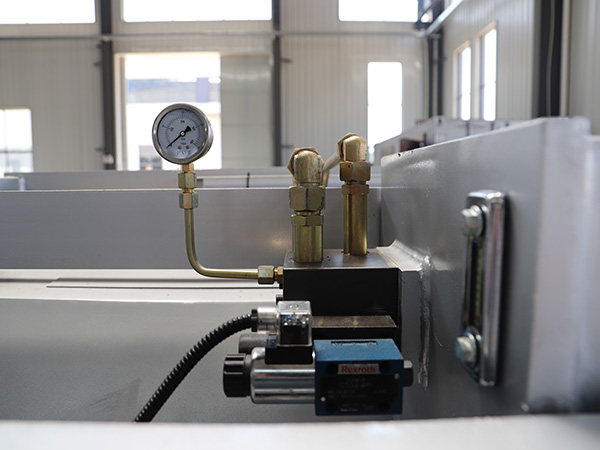

Hydraulic drive, return of knife beam is smooth and prompt by accumulator or nitrogen cylinder.

It adopts three point supporting type rolling guideway to raise shearing precision.

Rectangle knife which has four blades has a lasting life.

The portable and prompt adjustment of the blades gap and the value of gap are indicated by digital, convenient and fast.

Equipped with lighting alignment, so as to align when shearing, the stroke of knife beam can be adjusted in stepless model.

Protection fence to ensure to operation safety.

The display devices of the back-gauge value and the shearing times, displays on the front of the machine.

The shearing angle can be adjusted.

Standard Equipment:

Hardened blades.

– Top blades : 2 sides

– Bottom blades : 4 sideE21S controller.

600mm motorized backgauge system with 0,1 mm accuracy.

800mm side gauge and front support arms.

Metric and inch rulers.

Front, side and back safety panels which are suitable for CE norms.

Sheet sliding system.

Schneider Electric System.

Rexroth hydraulic system.

Moveable foot pedal.

Manual blade gap adjustment.

Emergency stop button.

Collapsible finger protection.

| Machine Paramters | |||||

| model | Shearing Thickness | Shearing Width | Strokes | Back gauge Range | Shearing Angle |

| (mm) | (mm) | (time/min) | (mm) | (.) | |

| 4*2500 | 4 | 2500 | 14 | 20-500 | |

| 4*3200 | 4 | 3200 | 12 | 20-500 | 1 30’ |

| 6*3200 | 6 | 3200 | 12 | 20-500 | 1 30’ |

| 8*3200 | 8 | 3200 | 8 | 20-500 | 1 30’ |

| 10*4000 | 10 | 4000 | 10 | 20-600 | 1 30’ |

| 12*6000 | 12 | 6000 | 5 | 20-600 | 1 30’ |

| 12*8000 | 12 | 8000 | 5 | 20-600 | 1 30’ |

| 16*3200 | 16 | 3200 | 10 | 20-600 | 2 |

| 16*4000 | 16 | 4000 | 10 | 20-600 | 2 |

| 20*4000 | 20 | 4000 | 5 | 20-600 | 2 30’ |

| 25*4000 | 25 | 4000 | 4 | 20-600 | 2 30’ |

| 32*3200 | 32 | 3200 | 5 | 20-600 | 3 |

| 40*3200 | 40 | 3200 | 3 | 20-600 | 3 |

| 50*3000 | 50 | 3000 | 5 | 20-600 | 3 |

| 50*6000 | 50 | 6000 | 5 | 20-600 | 3 |

| 60*3500 | 60 | 3500 | 5 | 20-600 | 3 30’ |