Project Description

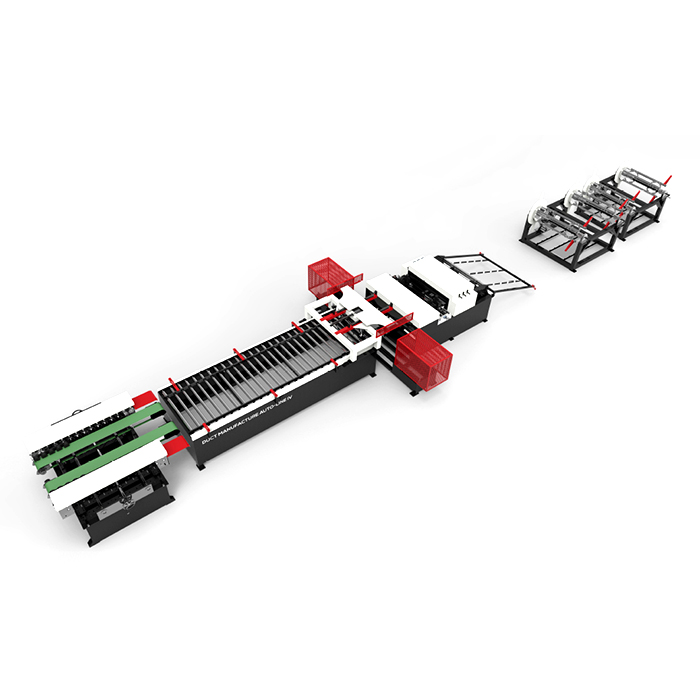

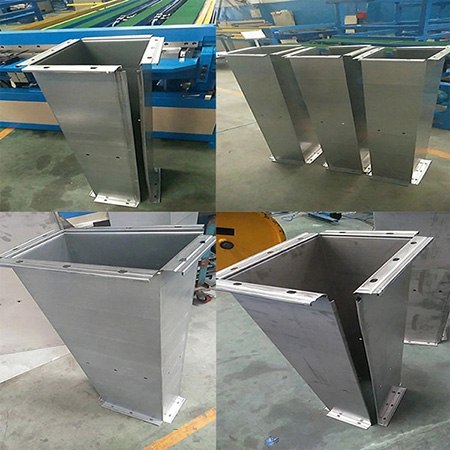

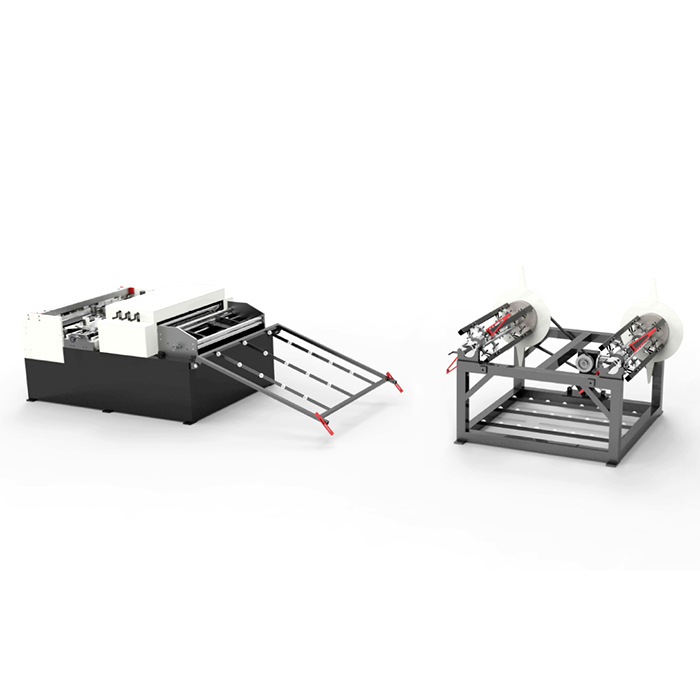

HVAC Rectangular Duct line Square duct Auto Production Line IV

Main Features:

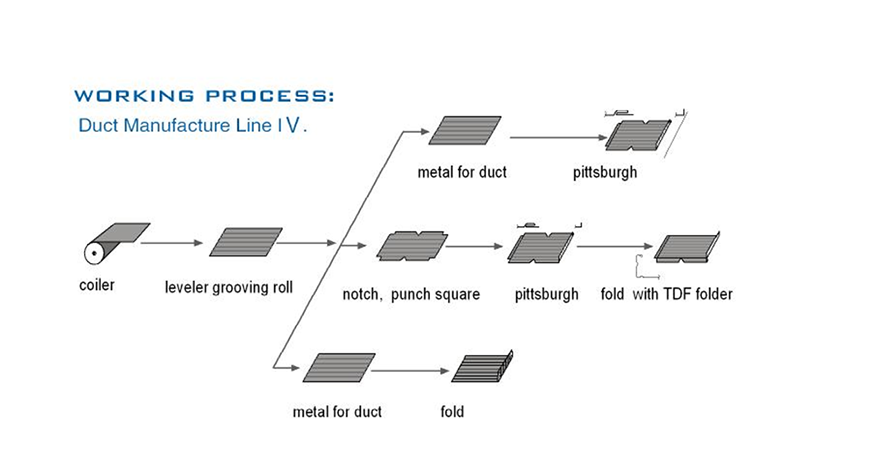

Duct production line Ⅳ composed of a decoiler, leveler grooving unit, “V” and “口” notching unit, cutting unit, bending unit,reciprocating lock former unit, feed extraman unit, duplex flange (angle iron & TDF) composition, the entire production process is controlled by the servo system is completed.

The production line has a cover an area of small, low energy consumption, easy to move, and high efficiency,

can produce a variety of rectangular duct. Control part with a separate console; the control system has a closed-loop feedback system, significantly improved accuracy and stability.

Duct automated production lines feed rate of 15m / min, length tolerance is ± 0.5mm, diagonal tolerance is ± 0.8mm;

MITSUBISHI HMI Display And PLC

MITSUBISHI Frequency Converter

Japan NEMICON Inverter

Taiwan Hydromax Pump

Taiwan High Temperature Resistant Tubing

Basic Configuration:

Two electric coil cradles, 4 material trays (5-7t each roll)

One rack

One host (line 2 host)

One mechanical arm clutching, locating and transferring platform

One movable locking machine

One duplex TDF flange forming machine

One duplex angle steel flange forming machine

One servo feeding platform

One hydraulic folding machine

One set of computer controlling system

| Technical Data | ||

| Model | DML-VI-1250 | DML-VI-1550 |

| Thickness (mm) | 0.5-1.2 | 0.5-1.2 |

| Max width (standard) (mm) | 1250 | 1550 |

| Max working speed( m/min) | 16 | 16 |

| Coiler Max-weight (KG) | 8000 | 8000 |

| Power (KW) | 19 | 20 |

| Weight | 10000 | 12000 |

| Dimension | 18000*3400*1500 | 18000*3600*1500 |