Project Description

WE67K Series Full Automatic Cnc Press Brake with DA66T 3D Programming CNC Controller System

Machine Instroduction

·New EU streamlined design

·The whole frame of the press brake adopt integrated welding, and by tempering to eliminate the internal stress

·The press brake frame adopt shot blast to remove rust and sprayed with anti-rust treatment

·The frame is formed by the imported CNC three-dimensional machining center in one process, which ensures the parallelism and verticality of each mounting surface.

·The controller can control the Y1 and Y2 axes (Y1 controls the left cylinder and Y2 controls the right cylinder) to ensure the synchronous movement of the ram

·Quiet speed waiting and fast down, (about 25 decibels), low noise during pressing and return (the pressure in the hydraulic system is the closed loop control of the servo main motor)

· The main oil pump does not apply work under the drive of the servo main motor, and the energy consumption is 60% lower than that of the general CNC press brake machine

· The machine oil temperature is stable, which extending the service life of various components of the hydraulic system

· More technical innovations to ensure the quality of bending, and powerful, easy to operate

· The press brake adopt the latest high-frequency hydraulic control technology, which is faster, more efficient and more stable

· The best parameter ratio, the optimal core configuration, the performance is stable, the operation is more convenient, and the bending of various workpieces in complex shape can be realized.

DELEM DA66T control system:

- Main body manufacturing by the CNC flooring and boring machine.

Technical utilize parametric 3D SolidWorks analysis.

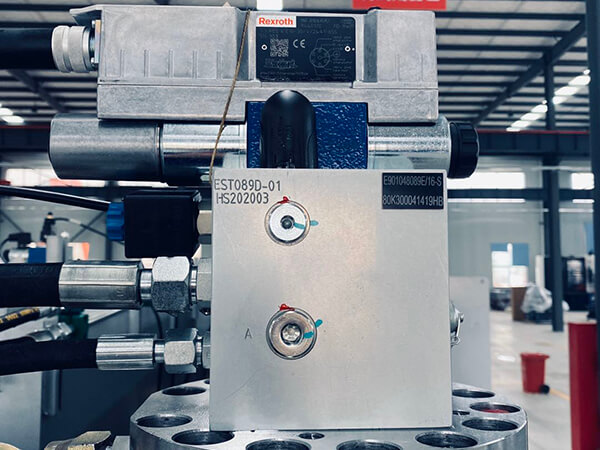

Adopt integrated hydraulic system, more reliable and easy for maintenance.

Mechanical synchronous mechanism and the complex compensation are designed so as to raise the working piece precision.

The stroke and distance of the back gauge is adjusted by the motor and is well adjusted by hand, the adjustment is displayed by digital meters.

Inch, single, continuous operation mode being designed for the machine and reversing and maintain time can be controlled by the time relays.

Safe fence and the electric interlocker have been designed for the machine to ensure the operation safety.

Strict manufacturing process keep product standard reach Euro standard

Standard Equipment:

HIWIN Ball screws &Polished rod with 0.05mm accuracy

Plate Support Arms

Telemecanique/Schneider Electrics

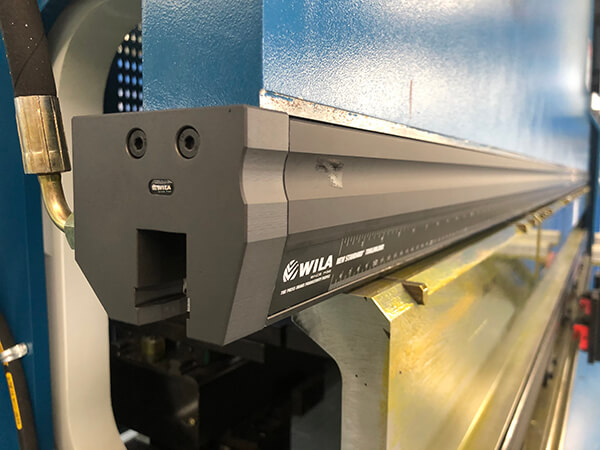

Germany Bosch-Rexroth Hydraulic

Germany Siemens Main Motor

Hydraulic & Electrical overload protection

Protection facility -laser protection

| Technical Specifications | |||||||||

| Bending Force | Bending Length | Upright Distance | Throat Depth | Stroke | Opening Height | Main Motor | Weight | Overall Dimensions | |

| Kn | mm | mm | mm | mm | mm | Kw | Ton | L×W×H mm | |

| WC67K/E-30t/1600 | 300 | 1600 | 1300 | 200 | 80 | 220 | 5.5 | 2.3 | 1650*1200*1700 |

| WC67K/E-30t/2000 | 300 | 2000 | 1300 | 200 | 80 | 220 | 5.5 | 2.5 | 2000*1150*1700 |

| WC67K/E-40t/2500 | 400 | 2500 | 2030 | 250 | 100 | 340 | 5.5 | 3.5 | 2500*1200*1900 |

| WC67K/E-63t/2500 | 630 | 2500 | 2050 | 250 | 120 | 340 | 5.5 | 4.5 | 2500*1600*2200 |

| WC67K/E-63t/3200 | 630 | 3200 | 2510 | 250 | 120 | 340 | 5.5 | 5 | 3200*1600*2200 |

| WC67K/E-80t/2500 | 800 | 2500 | 2050 | 250 | 120 | 350 | 5.5 | 6 | 2500*1700*2200 |

| WC67K/E-80t/3200 | 800 | 3200 | 2510 | 250 | 120 | 350 | 5.5 | 6.2 | 3200*1700*2200 |

| WC67K/E-100t/2500 | 1000 | 2500 | 2050 | 320 | 120 | 380 | 7.5 | 6.5 | 2500*1500*2200 |

| WC67K/E-100t/3200 | 1000 | 3200 | 2510 | 320 | 120 | 380 | 7.5 | 7 | 3200*1800*2500 |

| WC67K/E-100t/4000 | 1000 | 4000 | 3100 | 320 | 120 | 380 | 7.5 | 8.5 | 4000*1800*2500 |

| WC67K/E-125t/3200 | 1250 | 3200 | 2510 | 320 | 120 | 380 | 7.5 | 7.5 | 3200*1900*2600 |

| WC67K/E-125t/4000 | 1250 | 4000 | 3100 | 320 | 120 | 380 | 7.5 | 9.5 | 4000*1435*2600 |

| WC67K/E-160t/2500 | 1600 | 2500 | 2050 | 320 | 200 | 450 | 11 | 9 | 2500*1900*2700 |

| WC67K/E-160t/3200 | 1600 | 3200 | 2510 | 320 | 200 | 450 | 11 | 11 | 3200*2000*2800 |

| WC67K/E-160t/4000 | 1600 | 4000 | 3040 | 320 | 200 | 450 | 11 | 12 | 4000*2000*2800 |

| WC67K/E-160t/5000 | 1600 | 5000 | 3800 | 320 | 200 | 450 | 11 | 14.5 | 5000*1900*3100 |

| WC67K/E-160t/6000 | 1600 | 6000 | 4600 | 320 | 200 | 450 | 11 | 19.5 | 6000*1900*3300 |

| WC67K/E-200T/3200 | 2000 | 3200 | 2600 | 320 | 250 | 540 | 15 | 13.5 | 3200*1820*3300 |

| WC67K/E-200T/4000 | 2000 | 4000 | 3300 | 320 | 250 | 540 | 15 | 15 | 4000*2000*2850 |

| WC67K/E-200T/5000 | 2000 | 5000 | 3800 | 320 | 250 | 540 | 15 | 19 | 5000*1950*3000 |

| WC67K/E-200T/6000 | 2000 | 6000 | 4600 | 320 | 250 | 540 | 15 | 21 | 6000*1950*3300 |

| WC67K/E-250T/3200 | 2500 | 3200 | 2600 | 400 | 250 | 580 | 18.5 | 17 | 3300*2000*3200 |

| WC67K/E-250T/4000 | 2500 | 4000 | 3300 | 400 | 250 | 580 | 18.5 | 20 | 4000*2000*3400 |

| WC67K/E-250T/5000 | 2500 | 5000 | 3800 | 400 | 250 | 580 | 18.5 | 23 | 5000*2000*3500 |

| WC67K/E-250T/6000 | 2500 | 6000 | 4600 | 400 | 250 | 580 | 18.5 | 25.5 | 6000*2000*3600 |

| WC67K/E-300T/3200 | 3000 | 3200 | 2600 | 400 | 250 | 580 | 18.5 | 21 | 3200*2100*3300 |

| WC67K/E-300T/4000 | 3000 | 4000 | 3300 | 400 | 250 | 580 | 18.5 | 23 | 4000*2100*3500 |

| WC67K/E-300T/5000 | 3000 | 5000 | 3800 | 400 | 250 | 580 | 18.5 | 25 | 5000*2100*3700 |

| WC67K/E-300T/6000 | 3000 | 6000 | 4600 | 400 | 250 | 580 | 18.5 | 27.5 | 6000*2100*4000 |

| WC67K/E-400T/4000 | 4000 | 4000 | 3300 | 400 | 250 | 580 | 22 | 26 | 4000*2200*3600 |

| WC67K/E-400T/5000 | 4000 | 5000 | 3800 | 400 | 250 | 580 | 22 | 32 | 5000*2200*3900 |

| WC67K/E-400T/6000 | 4000 | 6000 | 4400 | 400 | 250 | 580 | 22 | 35 | 6000*2200*4100 |

| WC67K/E-500T/4000 | 5000 | 4000 | 3300 | 500 | 320 | 620 | 30 | 33 | 4000*2400*3900 |

| WC67K/E-500T/5000 | 5000 | 5000 | 3800 | 500 | 320 | 620 | 30 | 37.5 | 5000*2400*3900 |

| WC67K/E-500T/6000 | 5000 | 6000 | 4410 | 500 | 320 | 620 | 30 | 43.5 | 6000*2450*4250 |

| WC67K/E-500T/7000 | 5000 | 7000 | 5400 | 500 | 320 | 620 | 30 | 55 | 7000*2550*4350 |

| WC67K/E-600T/4000 | 6000 | 4000 | 3300 | 500 | 320 | 620 | 37 | 45 | 4000*2700*4700 |

| WC67K/E-600T/5000 | 6000 | 5000 | 3800 | 500 | 320 | 620 | 37 | 48 | 5000*2700*4750 |

| WC67K/E-600T/6000 | 6000 | 6000 | 4600 | 500 | 320 | 620 | 37 | 55 | 6000*2700*4950 |

| WC67K/E-600T/7000 | 6000 | 7000 | 5400 | 500 | 320 | 620 | 37 | 62 | 7000*2700*5150 |